G4APV's EB104

Construction Page

EB104

This

web page

contains a sort running log about the construction of a MRF150 based

600W linear amp. The basis of the amp is an old but reliable

design by Motorola that came out as Engineering

Bulletin 104,

hence EB104.

Case

The

case came from Maplin.

Parts

So what goes into the case? Here is the kit of EB104 parts

that I

got

from Communication

Concepts for the amplifier

itself:

Attenuator

As

well as that I needed a few other parts, these are for the

attenuator to drop 20W down to 6W. This 6dB odd loss ensures

that

most HF transceivers with a typical low power output of about 10W can

be used to drive the amplifier with a bit of a margin of safety.

It also ensures the input impedance to the amplifier is more closely

controlled. The parts came from mainly from JAB

components.

Hardware

I

quickly came to the conclusion I would need quite a few nuts, bolts and

other hardware. I used M3 and M4 nuts and bolts as they

fitted the devices.. This lot came from Farnell:

Thermal Issues

WIth 600W out and about 60% efficiency then there is as much as 400W to

get rid of. This means getting the heat away from the devices

with a copper spreader and then getting rid of it with a heatsink.

Both the

spreader and the heatsink also came from Communication Concepts:

I was not confident about pure convection and so went for forced air

cooling using mains fans, again from Ebay.

Power

Supply

The

amplifier

runs of 50V and with 600W out will need about 1000W in, ie 50V at 20A.

To

power

this an ELTEK

brand new power supply off Ebay

but sold by Anchor

Surplus

in Nottingham is ideal. It is nicely protected and can be

started

up by a 5V control line. This allows it to be powered down on

receive to avoid nasty noises from the switching, although in practice

it seems to reasonably quiet anyway:

Auxiliary Power

I decided to use 12V for control systems to provide compatibility with

other systems I had. I got a 12V PSU, again off Ebay, shown

here

with

the cooling fans.:

If

you

are really interested (or is it sad?) then here is the

spreadsheet with all parts as

ordered

(except Ebay).

Main

Board Assembly

Before the board can be assembled, there is a great deal of mechanical

work to be done to mount the heat spreader onto the heatsink and then

mount the unpopulated PCB onto the spreader. Only when all of this is

done is it appropriate to put the components onto the amplifier board.

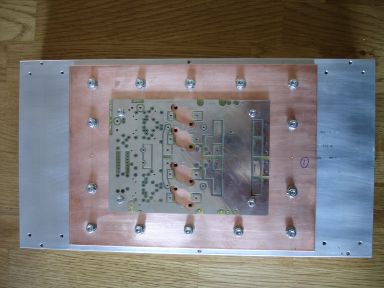

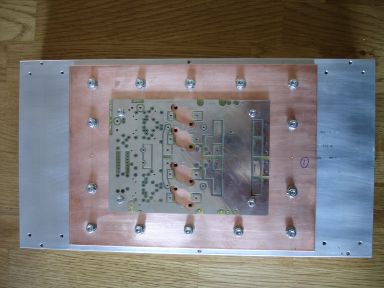

After much planning, drilling and tapping here is the PCB on the

spreader, with the spreader, on the heatsink. I found it

critical

to have a pillar drill to do this. I went and bought a

£55

one, new, from Machine Mart.

Here's the trial of the board on the spreader and heatsink:

Population of Board

This

a fairly long winded process with components on the top and the bottom

of the board. On the bottom of the board are some chip caps.

The board needs to be just clear of the spreader to ensure

these

don't short:

I next fitted the solder pins, and in retrospect the two big resistors

that are part of the feedback loop (below) should have been on pins, it

would make life much easier later on:

Putting the rest of components on gives:

Power

Devices

After various trial fittings, marking out, drilling and tapping of the

spreader and finally checking for shorts, the board was fitted to the

heat spreader and the devices soldered in:

Notice the 1W resistors have got a bit bent to allow access to the

device screws. Next time they will go on solder posts.

Initial

Testing and Bias Setting

At this point I decided to be brave and put the supply on and,

hopefully, set the bias currents. I bodged up a 3A fuse (just

because I had one) and monitored both the voltage and the current.

I am fortunate to have a 0 - 50V, 40A variable PSU

which

makes life easier. Here is the bodge up of the first test:

It proved to be pretty easy to set the bias current to 1A total, ie

250mA per device. As I was taking it up from the initial

supply

voltage of 40V to 50V as a check there was a bang, a blue flash and a

blown fuse - not good. It turned out to be a small offcut

strand

of wire across one of the devices. There is a lesson here

about

cleaning the board before testing!

Gain

Test

The next check was to see if it amplified. I used a signal

generator which has a maximum output of 19dBm (ie about 100mW) at 14MHz

to see what would happen. Thsi produced about 5 or 6W into a

50

Ohm dummy load which seemed ok to me. The next check was to

use

an FT817 (out of picture) to provide some RF as this can have it's

output reduced down to about 100mW.

Attenuator

Board

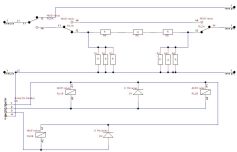

Once I had established the amplifier board itself seemed to be working,

I designed the attenuator. The actual design of the component

values was done using WinAtt

from GM4PMK on G3SEK's webpages. I used TinyCAD

for the schematic capture, FreePCB

for routing the board and ViewMate

to

print to pcb out.

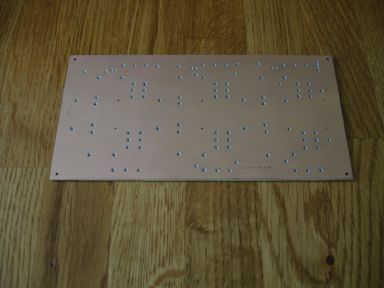

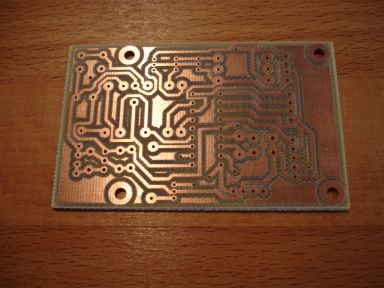

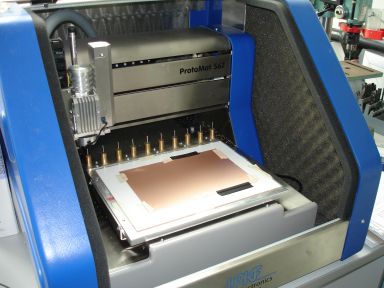

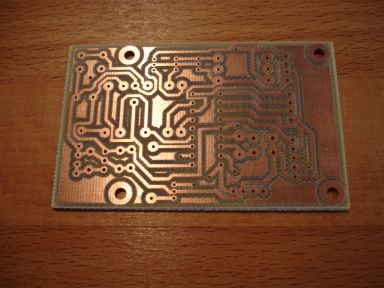

I

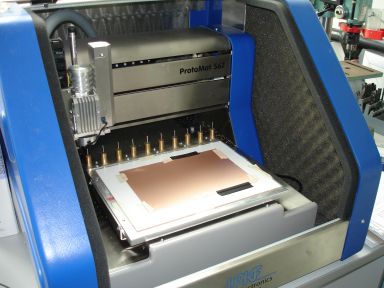

got

the board made at

work using a prototyping system

that uses a routing technique to

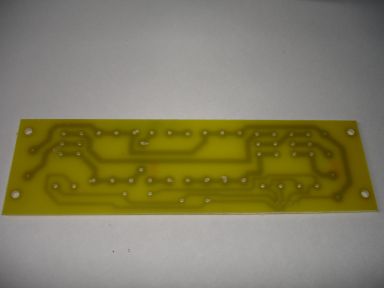

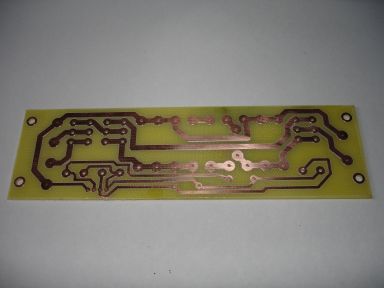

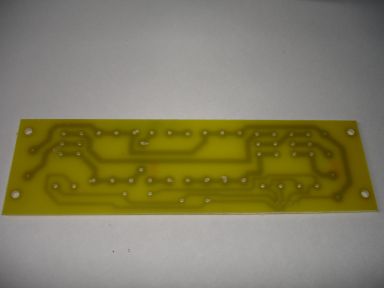

remove copper from those areas where it is not wanted:

Another idea I investigated but did

not

really got to work properly is the

"iron

on" technique. The

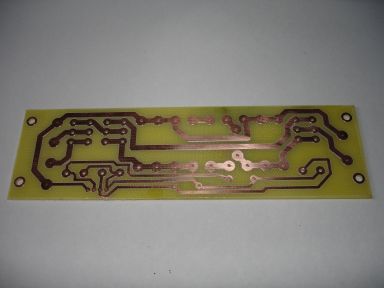

finished, routed boards come out ok, but

are obviously not plated, but that I can live with:

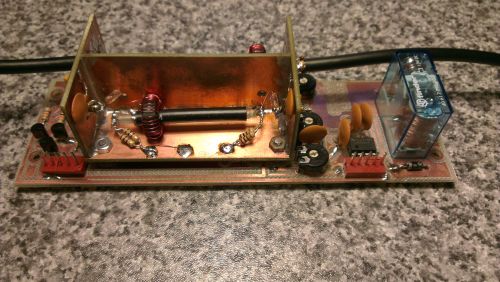

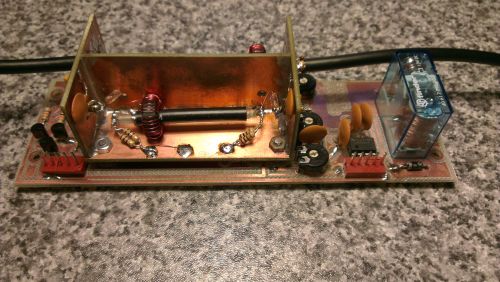

Here

it is populated, fitted but not

yet wired in:

I

then bodged on an output

transmit/receive relay and the 12V power supply to give a complete

working system:

Output

Switching

and SWR Board

To

protect the devices it is clearly

necessary to shutdown the amplifiier in the event of high SWR, for

example a flashover in an ATU. Also a relay for

transmit/receive

swithching ant the output is needed. I then designed a board

to

do this, it removes the 50V bias supply if it detects excessive SWR at

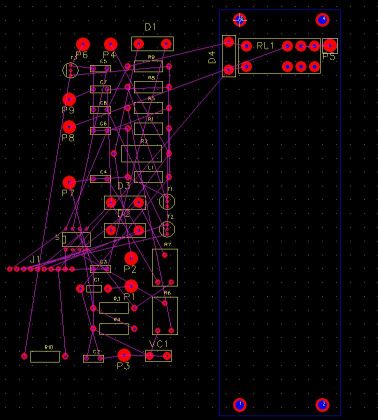

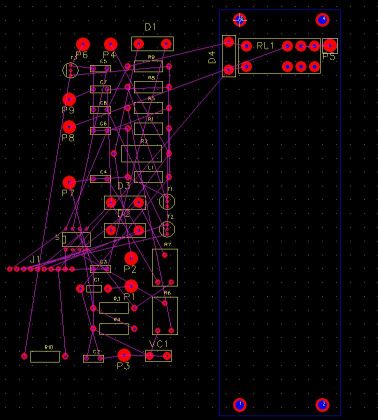

the output:. The PCB

layout starts as a schematic capture and is then imported into EasyPCB

to give "ratlines":

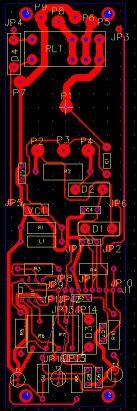

The

final result looks like:

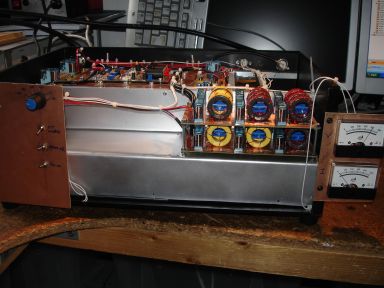

Mounting

in the

Case

Much

of the time was spent puzzling

out how to mount all the bits in the 19" rack mount case.

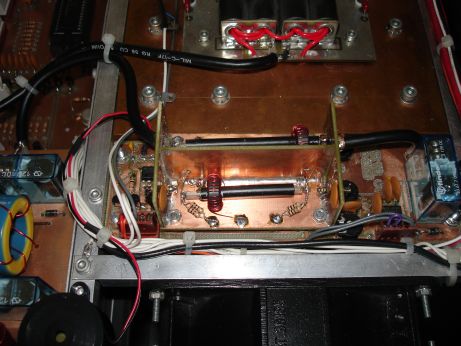

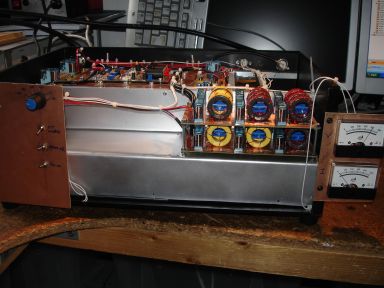

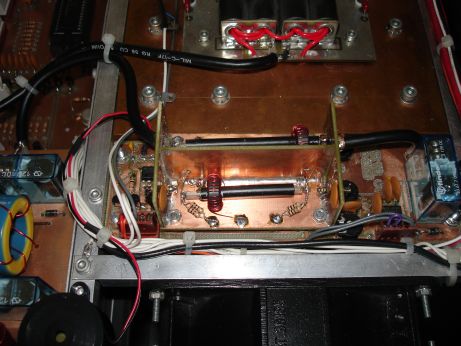

Here is

the stage with the amplifier, input and output boards and power

supplies mounted. The cooling fan, output filters and front

and

rear panels have not yet been dealt with.

Here

are the major components

installed and wired up. The amplifier is now usable but is

minus

the output filters. Some low level instability in the

amplifier

disappeared with the input and output SO239 and fitted and the power

supplies properly wired in

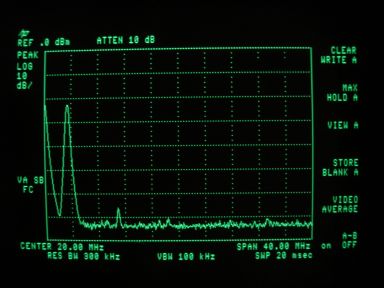

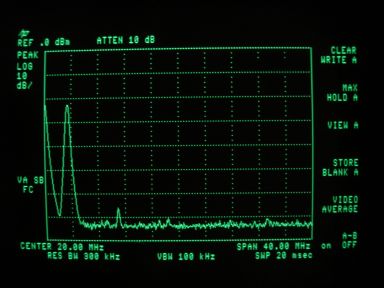

At this stage the lack of filters means the output was not

too clean, this was on 80m, some harmonics are only some 25dB down on

the fundamental:

The other lesson is not to push things to hard. The bypass

caps

on the drains supply don't like too much RF current. While

trying

to see how much power I could get out of it I discovered they go bang

and burst into flames. Here is the aftermath of this

happening,

the remaining leads in the plated through board were very difficult to

remove.

It seems as if too many harmonics are the problem which leads nicely

into the design of the output filters.

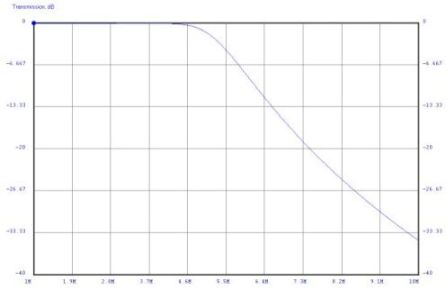

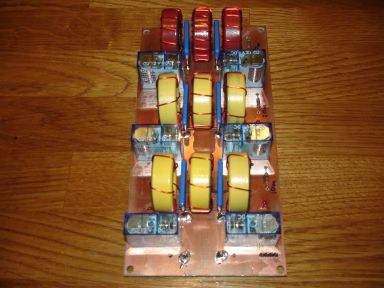

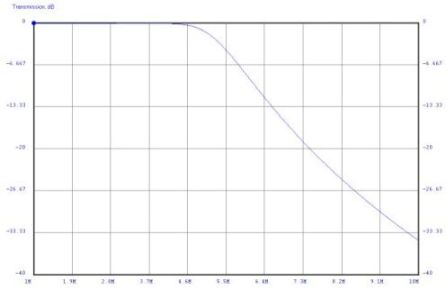

Filters

It seems to be fairly well established that a 5th order Chebyshev

design is appropriate for removal of harmonics from power amplifiers.

The design of the filters was based on the ARRL

Standard Value Capacitor

(SVC) tables. Once

the values had been calculated they were

modelled using ELSIE.

Using information I already had (not

sure where it came from) it became clear that a T-130-2 ferrite would

handle the power and provide the necessary inductance. An

example

of the design process is given in this

document.

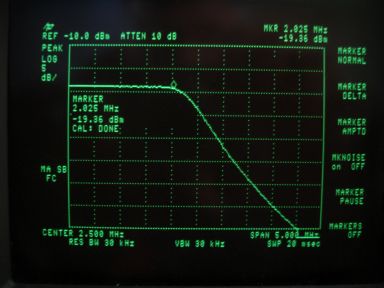

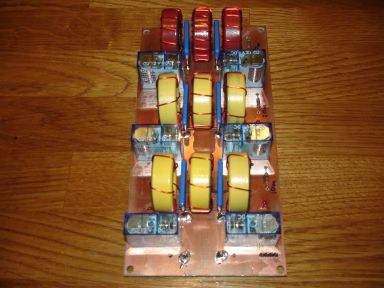

I

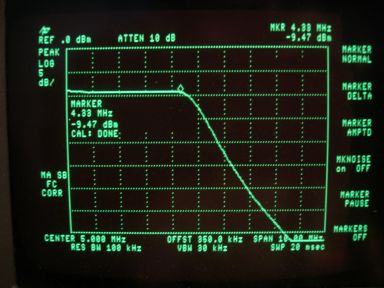

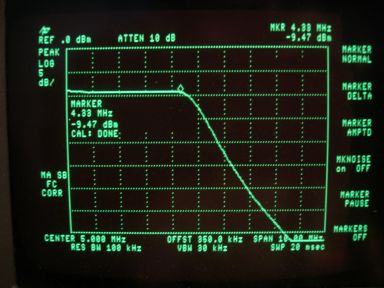

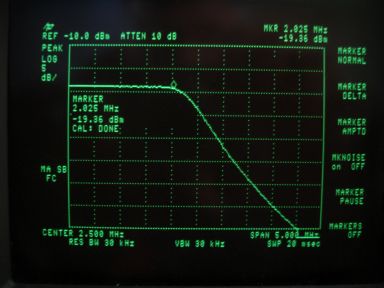

put together a prototype of the

3.5MHz filter as well as simulating

it: I then used a Panasonic VP-8191A signal generator plus a

HP8590A

spectrum analyser set to peak hold to find the filter's response:

I

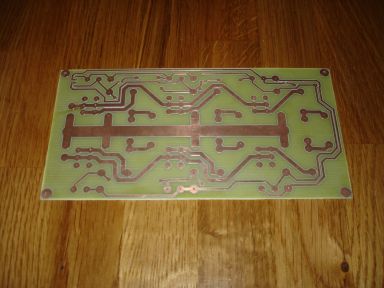

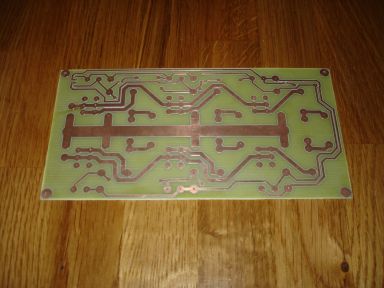

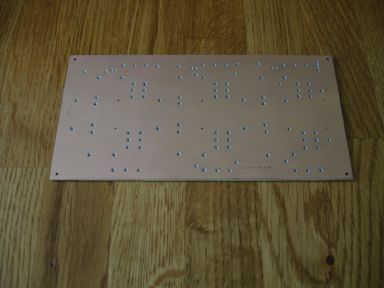

decided to put 3 filters on a PCB

and then use 2 boards to cover all bands. This was in an

attempt

to keep the track lengths acceptable. It seemed a bad idea to

have lots of RF going down long tracks. The higher the

frequency,

the shorter the track ought to be. I used an earth plane

approach in attempt

to cope with the potentially high RF currents. The unpopulated boards

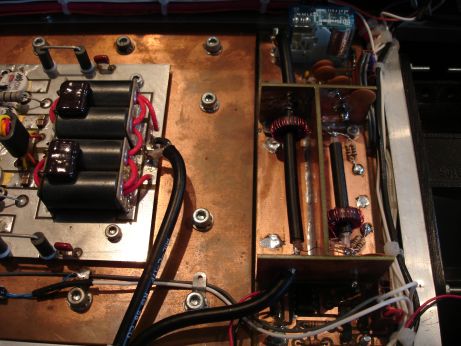

look like:

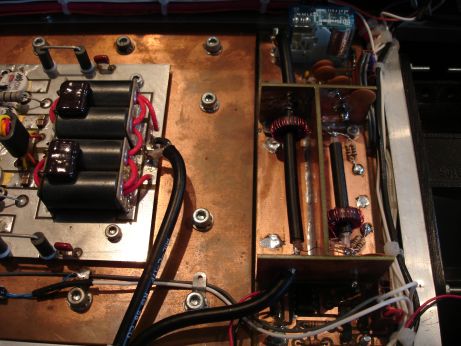

And once populated and the topband filter tested:

The second board was built and tested. I then stacked them

using

some M3 studding and wired it all up:

These photos also show the tray made out of bend and painted steel that

carries the boards and acts as a duct for the cooling air.

The

left hand side where the space is is where the control board will

eventually go.

Using the amplifier on

160m

and 80m at about 350 - 400W it

developed a fault where it would become erratic on transmit.

The

power output would disappear and then reappear. This did not

appear to be related to band, drive level, output power level etc.

At this stage I bodged on some meters to watch the supply

voltage

and current (see below). Of course it did not do it again

although I did

get it to smoke while giving it a long wwwaaaahhhhh. I

suspected

that the PSU was going into some sort of shutdown, but not due to over

current as the drive level did not affect the problem. I

suspected

RF getting into the control circuitry of the PSU.

Monitoring the voltage

and

current

soon showed the problem was not the PSU. Putting an old SWR

bridge

onto the input showed a very poor match and that the drive from the

IC735 was disappearing when the problem occurred. My

conclusion

is

that rig was shutting down as it got warm due to a poor mismatch (or is

that a double negative?). The solution is to run the IC735

via

the 6dB

input attenuator so that it always sees a good match. The

problem

has

not happened again since keeping the attenuator in all the time.

However the filters do seem to be working, the second harmonic is now

some 45dB down on the fundamental on 80m. Compare this to the

earlier plot of no filter which had the fundamental only 25dB down.

The filter should, at about 7.5MHz provide about 20dB of

attenuation so, surprisingly, it seems to do wha the theory says it

should! The third harmonic now seems to have gone - good.

Front

Panel

At this point I started to look at the front panel design and the

associated control circuits to select the filters, attenuator etc.

I decided to go for "push to select" approach rather than

rotary

controls. Rotary controls and toggle switches could have been

connected directly to the relays etc but but aesthetically this would

have look amateur and I want to have a reasonably professional end

result. This will imply some form of logic to interface the

buttons to the relays etc.

The front panel is made from mainly off the shelf parts from

Farnell but the meters are from a rally.

The front panel layout was done using free software from Front Panel Express.

I used

this as it is intended for front panel work and so the dimensions and

positions can be easily controlled. I am fortunate to have an

office that is directly opposite the Graphic

Design

student's printing workshop, so I went and talked nicely to the

technician and got the screen printing done...... The

printing is

water based so I lacquered the blank panel to protect it.

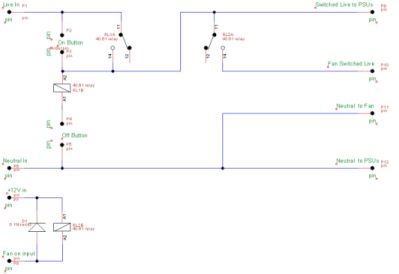

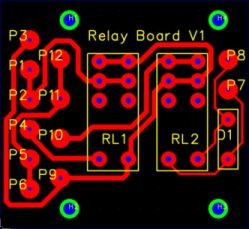

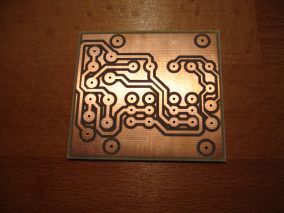

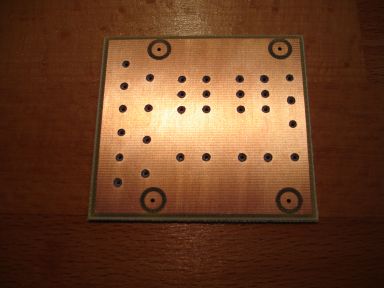

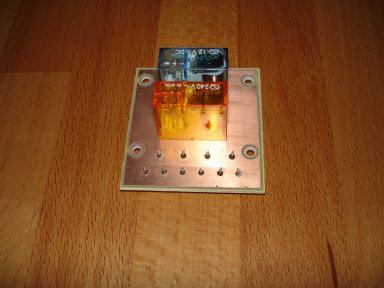

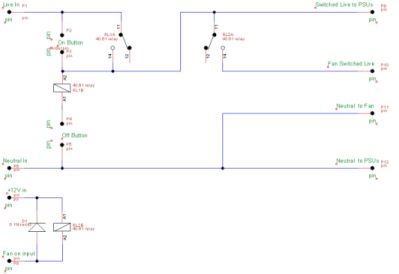

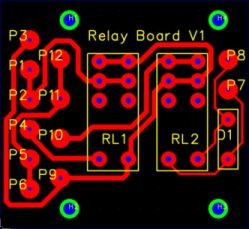

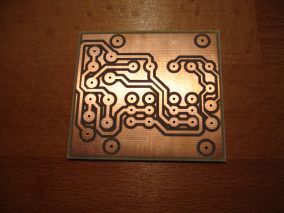

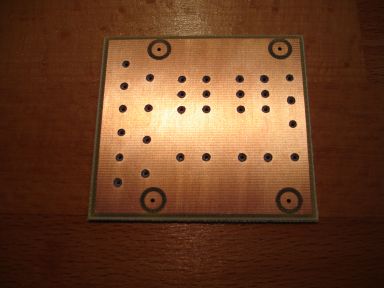

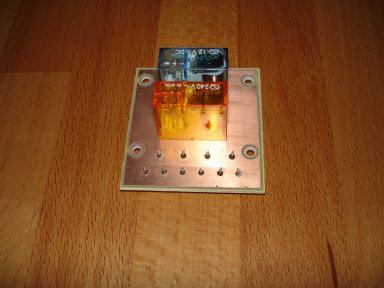

Mains Board

I

wanted a hard on/off with complete

isolation of the live from the psu when the amp was off. I do

not

like the psu to but in some sort of shut down mode. It is too

easy to end up with the supply on when you don't want it. The

on/off buttons feed a pcb with a mains relay that latches via

the

front panel buttons:

I've put this onto a pcb for neatness:

Here it is in place on the base plate next the 50V and 12V PSUs.

Control Logic

I thought I had a few options for the control logic each of which had

pros and cons:

- hard logic - significant

design

effort, hard to modify later but potentially simple and no EMC problems

- microprocessor -

significant

hardware and software design effort but flexible and I have programmed

in assembler before. Potential EMC problems from the clock

- Raspberry

Pi - this was a late

consideration. This met all my

connectivity, processing power and cost requirements BUT is

hard

to mount (no mounting holes), lots of cabling in strange positions to

cater for and, most importantly, it would need programming in a high

level language, probably C. I have no competence in any high

level language and accessing I/O ports is more complex - this was the

killer for me.

I

went for option 2 and chose a

PIC

as all the tools for generating the

code and loading the code onto the PIC is cheap and well documented.

After a lot of thinking I went for a two chip solution.

The

idea was to separate the control of the purely digital interface of the

front panel to the relays from the analogue functions (over

temperature mainly) and the comms function. I

intend to

include a CI-V interface to interface to my Icom radios so that the

amplifier is automatically on the correct band. It might add

Yaesu CAT as well if I can be bothered later on. For the

digital

interface I chose a 16F57

as this had the necessary number of digital I/O lines. To

date I

have been happy with this choice, with one exception. I

thought

it could

use ICSP (In Circuit Serial Programming), in fact it must

use this

method. This had the slightly annoying effect of

needing an

extra socket attached to my programmer.

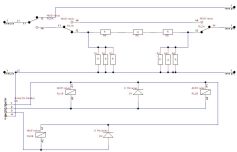

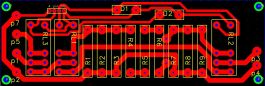

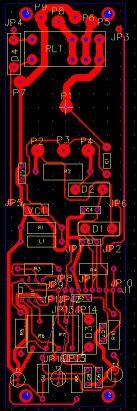

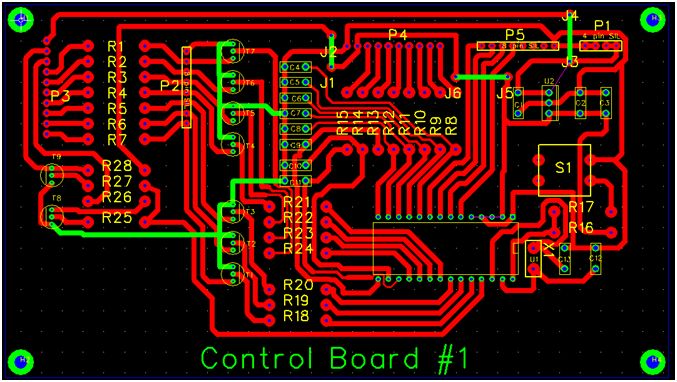

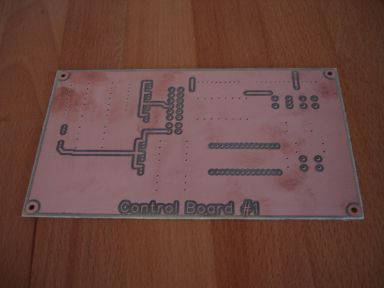

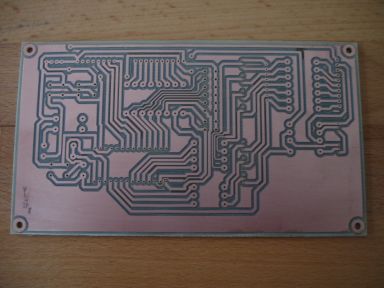

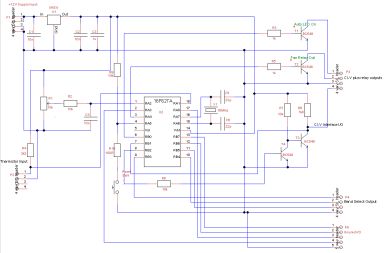

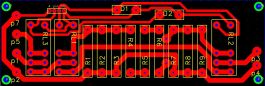

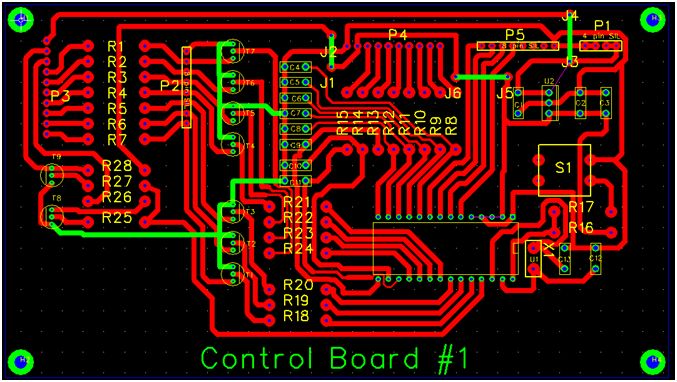

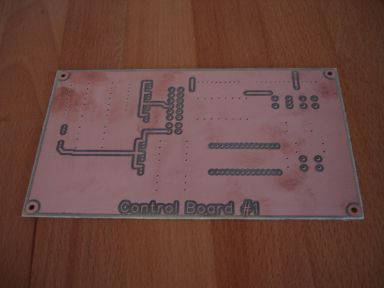

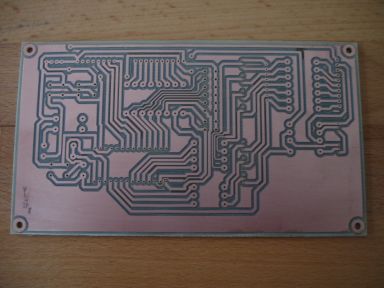

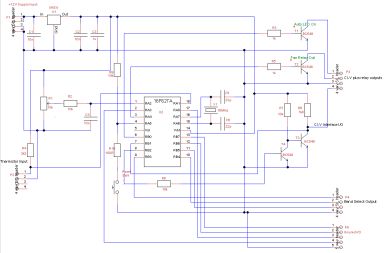

I designed a board using Tinycad and FreePCB as before.

FreePCB

has some problems in terms of producing the Excellon drilling file.

It seems to generate non compliant code. I checked

the code

using gerbv

and

hacked it (it's a text file) by hand until I cleared all the errors.

This is a double side board, but the top side only has a few links on

it. It was produced on the LPKF system as per the other

boards:

Having populated it and used it I would, in retrospect have done it

differently. I would have use SIL resistors to improve the

packing density, put ICSP on the board and put the digital controller

and analogue/comms PICs on the same board. The only problem

is

the sheer number of bus lines takes up a great deal of real estate and

I am loathe to use tracks that are too narrow as this is, effectively,

a prototype so hacks may be necessary - much easier on big tracks.

Here is board in the amplifier fully wired up:

In terms of writing the

code

for the PIC I used MPLAB IDE v8.86 available from Microchip

as a download. In

terms of how program, the manual

for the 16F57 is good, but you need more than this unless you are

really experienced. I used some ideas from here

and

most usefully from Gooligum Electronics who provide very good tutorials

which

should get most people going. To load the code onto the PIC I

used a Quasar Electronics 3128

PIC programmer but with a Vero

board extra to allow me to use ICSP

on the chip.

Version

one of the software

is now working, this provides control of the band, attenuator and

amplifier on button. The code is not sophisticated,

at this

stage I just wanted to get it working. This document

details the how the

PIC interfaces to the board. The PIC is now programmed such

that

the

board works correctly as the front panel interface for manual control.

It also now has the code to allow the second controller board

to

override the manual settings when it is automatic mode where the band

is set from the CI-V input from an Icom radio.

Communications Boards

This is the second processor board and it provides control of the

cooling fan based on the temperature and also will ensure the amplifier

automatically on the correct band. It will do this for Icom

radios initially. This is because I understand the Icom CI-V

bus,

have several Icom radios and finally I can't be arsed to do it for

Kenwood or Yaesu at this stage. The slow bit was writing the

code for it. I am

conscious that this will be time critical code so I will need to be a

bit more careful to avoid timing issues when programming the PIC.

The PIC I chose is the 16F627A as it provides the analogue

comparators needed for the temperature control as well as having the

UART needed for the CI-V interface.

Here's the design:

Currently I have got the

16F627A configured to use a comparator to turn

the fan on and off based on the temperature as measured by the

thermistor. This sounds simple but the different internal

architecture and the sheer number of configuration options meant it

took me a day to get this code working correctly. The nice

thing

is that now that this code is done I have a completely working

amplifier, albeit in manual mode only.

The auto band switching code is now written and working! It

proved to be easier than I expected the only the thing that caused any

problems was failing to set the global interrupt enable - that tends to

stuff things. If you really are interested then here is the

working code for control

board #1 and control board #2.

If you want to use my code that is fine but I would appreciate

acknowledgment of this if you in any way publish your code.

To

write the code a good understanding of Icom's CI-V code is needed, I

used a very old paper document that describes it for the IC735 but you

can find suitable information from Icom

or with a users perspective here.

Completed Hardware

.

Above are pictures of the current hardware which is more less

final - at least until I change it.

Software Updates

21 April 2013

I

have modified the software to ensure if band is changed automatically

then the amplifier is turned off. Otherwise it would be too

easy

to change band on the radio and go to transmit with the amplifier in

but without matching the aerial - not good.

The software will now

work

with any Icom radio not just the IC735.

The IC735 was the first radio to implement the CI-V and used

a 4

byte data string for the frequency rather than 5 used on later models.

The software can now cope with either, I've tested with an

IC706

and it works fine - only after 4 hours of messing about just

to

discover I had to enable the Transceive function on the IC706 for it to

produce data, oh well......

28 April 2013

I recently

bought a Kenwood TS480 which I am really enjoying playing with,

particularly the remote control abilities. Obviously I want

it to

able to control the amplifier so I have been looking at the Kenwood

Network System (KNS). The key document has been this

one. So far

I have gleaned a few things:

- it has a separate txd and

rxd

line (unlike CI-V which has a single line)

- standard RS232C voltage

levels

are used (+15V and -15V)

- it seems to only be

suitable

for one radio controlled by one PC (unlike CI-V which is a CSMA-CD

system)

- to get the rig to output

it's

parameters as they are changed on the front panel (as opposed to

interrogating it for its status) it has to have the Auto Information

set to on. This is done by sending it the command AI2; .

Unfortunately this is

cleared back to off when the rig is powered off.

I sent it a few commands

by hand to check

I understood this. To do this I used the terminal program Tera

Term.

This is very useful for checking things out. I have

reached

a few conclusions based on the above:

- the amplifier cannot just

passively monitor the data coming out from the radio as there won't be

any unless you send AI2; to the radio

- when the amp is turned on

it

will need to send AI2; as part of its start up sequence

- to have PC control of the

radio

via HRD

and

the amp connected, then

the

amp will have to take over the rxd and txd lines to the radio, send

AI2; to the rig, and then connect the lines back to the pc and HRD.

This will probably mean looping the radio to the amp and then

the

amp to the pc

- to ensure when the amp is

off

that HRD will still work then I may have to use relays to switch txd

and rxd

- the current comms board

will

need to be modified to bring out rxd and txd separately, currently they

tied together to drive the CI-V interface - I should have thought about

keeping them separate earlier.....................!

My

current thinking is to have an extra small board on the back of the

radio which feeds two 9 way D types, one from PC, one from radio.

The board will then have some relays for txd and rxd

switching

and some sort of control line to switch it for Icom, Kenwood, or even

Yaesu (if I can be arsed to do it). The only thing that

really

worries me is having to drill the chassis as I will have to do it with

all the electronics in the case. I'll see if I can borrow a 9

way

D type hole punch from work.

Switching

Noise.

The

switched mode 50V psu was causing

some switching noise on some bands, particularly 15m. However

it

does

have a control input

to turn it on, although checking showed the manual to be wrong on the

pin number; it is 12b not 12d. I

am using the input to power it down on receive, and then power up on

transmit. The only slight snag is that it takes a short time

for

the

50V to come up once the control line enables it. I could

measure

how

long it takes but I can't be bothered as there is nothing I can do

about it.

Bugs fixed:

- Output power varies band

to

band - this turned out to be the bias switching transistor not going on

fully. Reducing the base resistor fixed it.

- RF getting into the

processor

making it switch bands etc when on transmit - not good!. The

copper earth plane on top of the board (clearly visible above RF board

in the pic above) was not earthed. Obvious really, but it

took me

a while to find......

Bug

to still fix - RF output

varies band to band.

I've yet to figure this one out.

I suspect the filters are maybe presenting a poor match to

the RF

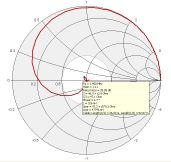

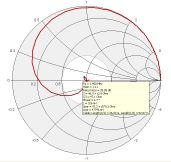

board. I've taken some Smith charts to see if there is a clue

there. Here's some results:

Top band in-band and at second harmonic which looks ok:

18MHz in-band and at second

harmonic which does not look ok:

Trouble is, they both seem to work all right so this is still work in

progress..........

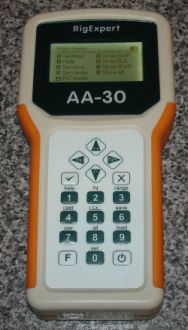

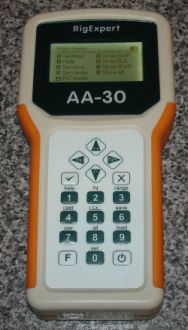

These plots were taken using a RigExpert

AA30

This is overtly an antenna analyser but is much more powerful than that

as it can determine Z, R and X, including the sign of X. Most

analysers don't seem able to do the sign of X. The user and

software

manual tell you more if you are interested.

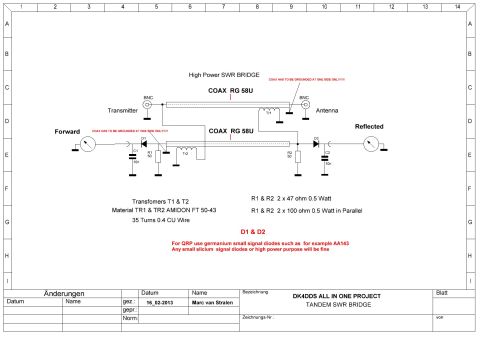

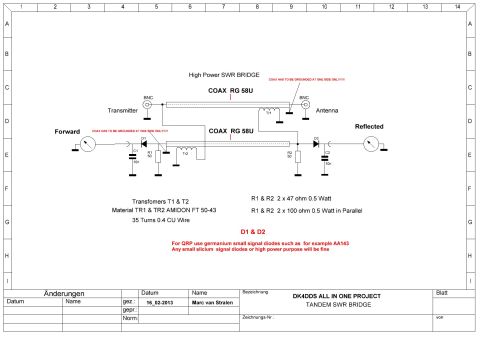

SWR

protection Board

The

original SWR protection board

just did

not work :-( I don't seem able to measure the SWR effectively

so

this board needed a redesign. Marc van Stralen, DK4DDS has

sent

me

some helpful information by Bill Leonard, N0CU. He also gave

me a

link to his All in one SDR TRX.

This is a

great project and includes a high power SWR bridge design which I have

partly replicated.

I have taken the SWR bridge parts and combined them with buffering and

latching circuits to provide protection. Here is Marc's

bridge

design:

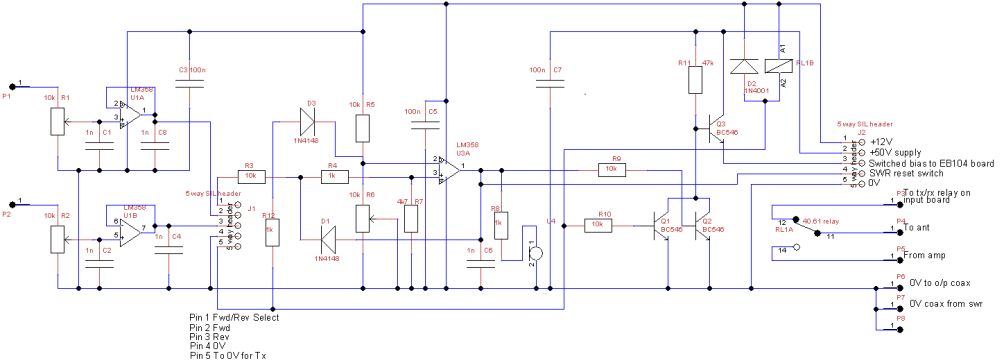

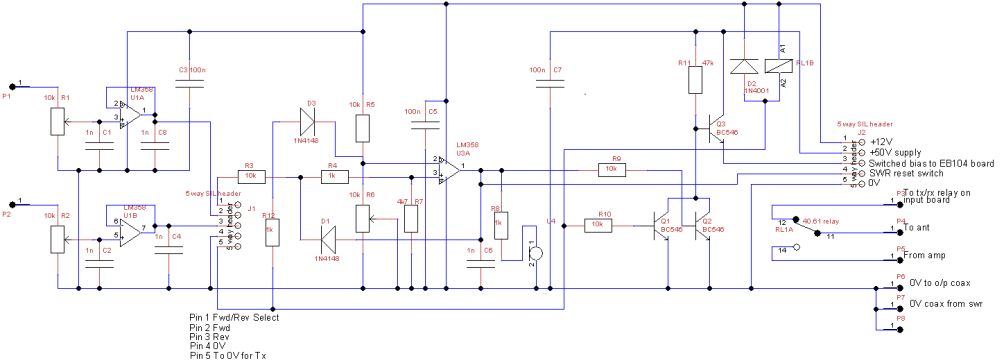

My implementation of this looks like:

The circuit to go with this contains buffers, a latch, a piezo

buffer to warn of excessive SWR plus some 50V bits to remove the bias.

If it works as I hope (!) then putting the amp back to

receive

should reset the latch. I haven't yet built it so we will

see.......

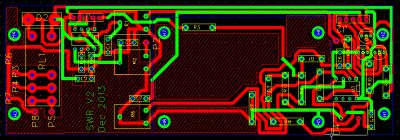

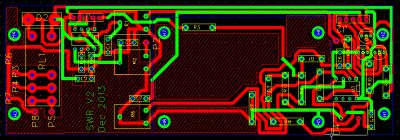

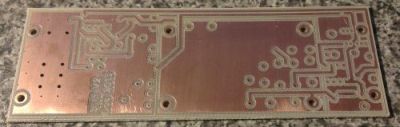

I have designed the PCB for this, the main problem is that the bridge

parts are rather big and so has to sit above the omp amp etc pcb.

The PCB is:

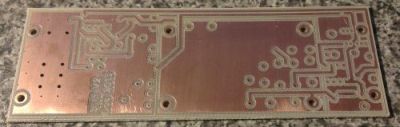

The populated board before fitting into the amp:

This is now fitted into the amp and works as intended. The

only

thing I had to do was to reduce R3 from 10k to 1k as the voltage at pin

3 of U3 was too small. Here it is in situ.

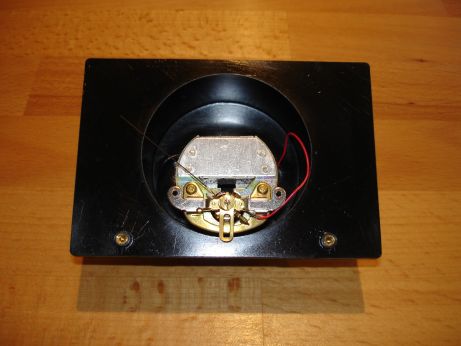

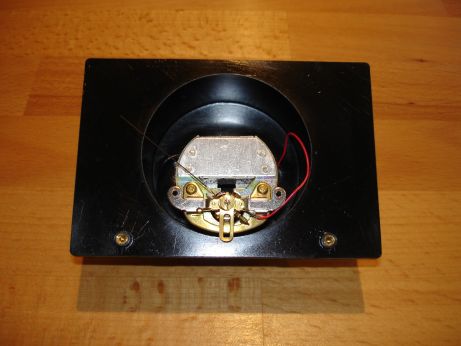

Meter Scales

I bought the meters for the drain current and voltage at a radio

rally (can't remember which or when) and although they are the right

size they obviously have the wrong scales. I did a bit of

Googling and found MeterBasic

at Tonne Software. This was ideal in terms of generating a scale

but the snag was how to get it on to the meters. I eventually

bought some paper intended for generating "decals" on models and

similar. I got this off Amazon from Mr Decal Paper. I

assume you can also get it from them directly.

It was not cheap at about £2 per A4 sheet but looked

suitable. The process was take the meter scales off, flip them

over, paint them white, put on the decal and then seal with a clear

lacquer. The process and outcomes are below, the paints are car

spray paints from Halfords.

Next job is to do a hardware mod and write some more code to allow this

to interface properly to Kenwood radios. There are lots of other

projects to do first though...................

Bob

Harris, G4APV, 3rd September 2014